by bob pastusek

by bob pastusek

Do you know how much useable fuel your Lancair holds? Unless you've personally checked this by testing, you don't know. This post is primarily aimed at second-owners of our Lancair fleet (more than half our members today, but if you are the builder of a flying aircraft and don't know how much useable fuel you have then you didn’t adequately test and validate your airplane. This is something that should be done before the first flight of any aircraft, whether you built it or bought it; what you don't know can hurt you; especially with home-built aircraft.

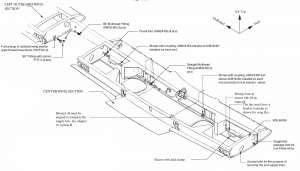

Lancair kits came from the factory in several configurations over the years. The first IV kits provided approximately 35 gallons of fuel in each wing tank, for a total of 70 gallons. Later versions raised this to 84, then 96, and later to 108 and even as much as 120 gallons. Many builders added belly and fuselage tanks for even more, and also plumbed their fuel systems in creative ways—not all of them improvements. But to the  point, there is no requirement to measure the usable fuel capacity of your just-acquired airplane, and no requirement to verify the fuel quantity indication system (the system is required, but there is no specification for accuracy or recurrent inspection). For most of us, the airplane endurance well exceeds our personal bladder endurance anyway. Still, if it hasn't happened to you YET, there will come a time when knowing how much fuel your airplane can carry, and how much you have aboard for any given indication on the panel, will be important—maybe even critical.

point, there is no requirement to measure the usable fuel capacity of your just-acquired airplane, and no requirement to verify the fuel quantity indication system (the system is required, but there is no specification for accuracy or recurrent inspection). For most of us, the airplane endurance well exceeds our personal bladder endurance anyway. Still, if it hasn't happened to you YET, there will come a time when knowing how much fuel your airplane can carry, and how much you have aboard for any given indication on the panel, will be important—maybe even critical.

Engine fuel control set up varies by manufacturer, but all piston-powered Lancairs require an initial fuel system set up to accommodate the aircraft-unique installation, inlet, filter and exhaust configurations. Both Continental and Lycoming also require system checks at 100-hour intervals or during the annual/ condition inspection. This is because the fuel flow changes as the engine wears normally. For Continental engines, SID97-3F specifies the required checks and fuel pressure/flow specifications. If you have a turbocharged engine, you'll also need to refer to the specific engine manual for turbocharger waste gate set up, which is a critical part of this calibration. (By the way, Continental Motors is revising their engine manuals to include all fuel system set-up information in one location. THANKS, Neal George!)

The just-released FAA Advisory Circular AC 90-116, Additional Pilot Program for Phase I Flight Test, requires the builder conduct and document fuel system checks prior to using a 2nd pilot during Phase I flight testing. This requirement is based on the fact (supported by LOBO analysis of Lancair accidents) that more than 1/3 of all Experimental-Amateur Built aircraft accidents are caused by fuel system problems, the majority of which are avoidable through system testing/validation on the ground.

Click here for a detailed article on Lancair fuel system testing and calibration. So if you've never checked the flow and capacity of your fuel system and/or verified that an engine fuel system calibration is accomplished annually, I strongly urge you to add these to your inspection/checks.

For questions/comments contact Bob at r.pastusek [at] lancairowners.com.